Solect Energy

There is a lot of buzz here in New England about energy storage and its potential in the commercial and industrial (C&I) sector. Working in tandem with a rooftop solar PV system, an energy storage system allows a facility to be nearly self sufficient: enabling it to generate its own power, store it and use it when needed. Building owners benefit by reducing expensive demand charges, avoiding time-of-use rates, providing power quality assurance, and enabling back-up power when needed.

These behind the meter energy storage systems are typically pre-configured, require little maintenance and are easily installed at a commercial facility. For the demands of the C&I market, lithium-ion batteries are currently the technology of choice. Their “energy profiles” match well with storing energy from the grid or a solar energy system and then deploying that energy over a shorter period of time. As is the case with any project, it is important that customers engage with a reputable vendor and installation partner.

Today we are going to show you what a C&I scale energy storage system looks like and how they are installed.

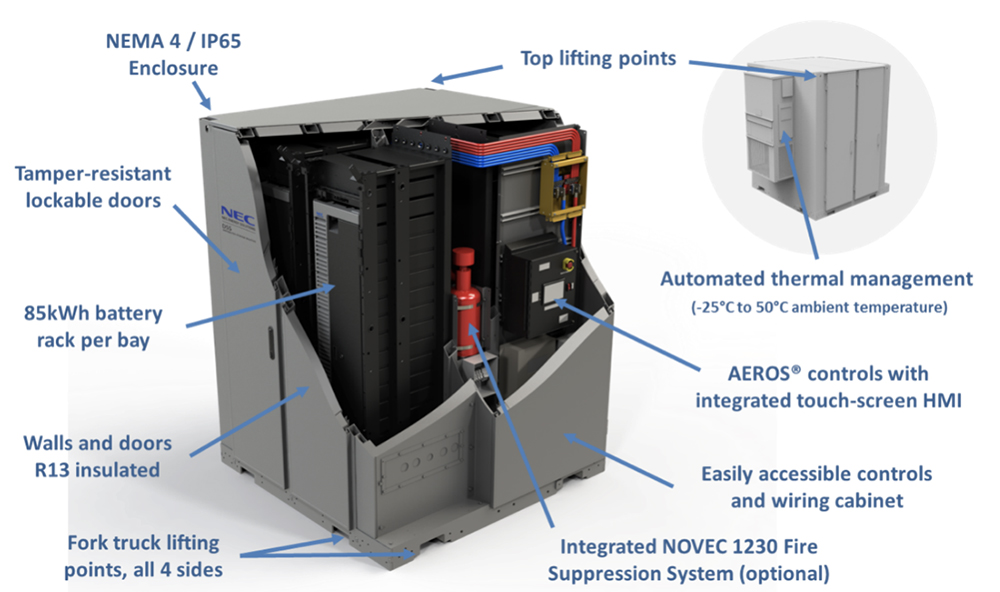

Energy storage batteries come in various sizes, and the best are scalable. For example, the schematic shows a fully contained unit, that can be scaled up from 85 kilowatt-hours to 510 kilowatt-hours of energy storage capacity, and between 30 kilowatts to 650 kilowatts of power capacity. Most commercial battery systems come with their own integration software or can be combined with other energy management software. The most sophisticated storage systems have been factory pre-configured and are optimized for rapid installation by qualified installation partners.

Typically, energy storage systems are located outside a facility. A concrete mounting pad is recommended. Site preparation includes minor excavation, pouring of a foundation and the positioning of conduits for power and communication connections. Wiring can be embedded into the concrete pad.

Depending on the size of the battery, either a crane or forklift can be used to position the battery. Typically the batteries are encased in secure, and tamper-resistant NEMA rated housing; security fencing may be required but that will be dependent on local codes. Finally, the battery can be secured with concrete anchors after installation.

A qualified installer can complete the electrical connections. These include between the battery and PCS (power conversion system), and the main and auxiliary power connections to the facility’s electrical panels. In addition, there will need to be connections for the meters and for communications such as Ethernet LAN for remote access and control. In some case cellular modems are used if a LAN is not available (security or remote). Installation of appropriate equipment grounding will also be required. A typical PV system will be located behind the meter and connected to the facilities main distribution panel. A typical energy storage system will be connected to a sub-panel.

A qualified installer can complete the electrical connections. These include between the battery and PCS (power conversion system), and the main and auxiliary power connections to the facility’s electrical panels. In addition, there will need to be connections for the meters and for communications such as Ethernet LAN for remote access and control. In some case cellular modems are used if a LAN is not available (security or remote). Installation of appropriate equipment grounding will also be required. A typical PV system will be located behind the meter and connected to the facilities main distribution panel. A typical energy storage system will be connected to a sub-panel.

One of the final steps, that is often dependent on local utility requirements, would be a grid interconnect validation and test witnessing. The last step is to conduct a system start up, commissioning and test.

Today’s battery systems are self contained and easy to site. Energy storage is an ideal complement to a solar energy system, giving greater control to property owners and facility managers to reduce their energy costs, increase their buildings resiliency and lower their carbon footprints.

John Mosher is vice president, energy solutions at Solect Energy, Hopkinton, Mass.