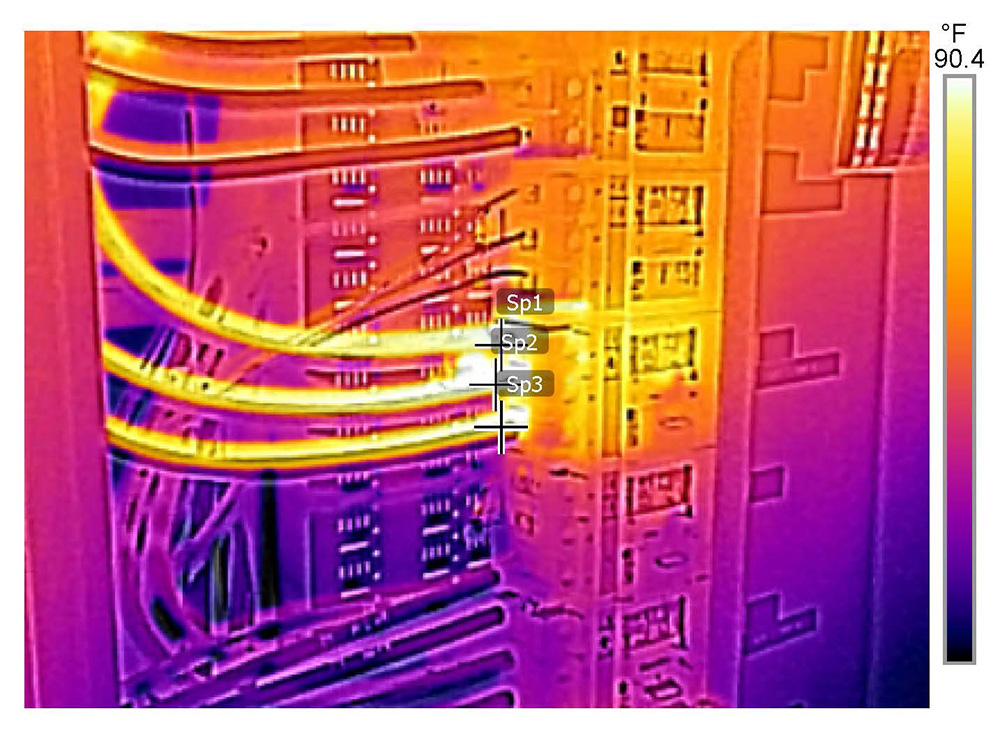

Thermal imaging cameras are a valuable tool for modern electricians. Using infrared thermography, these cameras can safely and accurately diagnose electrical problems by detecting excessive heat, a common cause of damage to electrical components.

Licensed electricians and thermographers use thermal imaging as part of a structured maintenance program. For example, they can scan a circuit breaker to check for loose connections, identify issues with breaker contacts that generate hotspots, or assess if the load on the breaker is properly balanced. After resolving any diagnosed problems, they use thermal imaging again to verify the effectiveness of the repair.

Thermal imaging also offers several advantages over traditional physical contact measurement techniques, which often require power to be shut off for safety reasons. With thermal imaging, power interruptions can be minimized, leading to less disruption for clients. Additionally, thermal images provide visual documentation of problems and solutions for customers. Furthermore, the real-time capabilities of thermal imaging allow electricians to monitor equipment as it heats or cools, aiding in diagnostics.

Thermal imaging also offers several advantages over traditional physical contact measurement techniques, which often require power to be shut off for safety reasons. With thermal imaging, power interruptions can be minimized, leading to less disruption for clients. Additionally, thermal images provide visual documentation of problems and solutions for customers. Furthermore, the real-time capabilities of thermal imaging allow electricians to monitor equipment as it heats or cools, aiding in diagnostics.

Recent advancements in thermal imaging technology, including higher resolution screens, smartphone integration, and laser-assisted focus for precise image positioning, have further enhanced its capabilities. By visualizing heat, electricians can identify and resolve issues faster, improving project efficiency.

Having licensed thermographers on your team can provide valuable insight into a project very quickly. The use of thermal imaging helps to reduce diagnostic time and optimize projects. By routinely performing these diagnostic services, facilities can extend the life of their critical power systems.

Brian Leborgne is a regional manager - service with Interstate Electrical Services Corp., North Billerica, Mass.