David Richman was looking for a leasing company in February 2010 to finance a new equipment purchase for his company. What a deal he found! The person who answered the phone was Dan Thompson from Greffen Systems, who politely said, "I am not in the financing business anymore; I help building owners reduce their cost of oil and gas." Richmond owns commercial buildings and immediately called his friend Mark Paley owner of Harvest Properties, a large commercial and residential building management company, and said please check out this GIZMO thing called the M2G and see if it works and will I(we) reduce our energy costs. Paley called his HVAC contractor, John Mitchell Jr., president of Mitchell Fuel Company based in South Windsor. Mitchell agreed to install the M2G in some of Paley and Richmond's buildings in March 2010. Mitchell has been in the heating and cooling industry for 35 years and was really skeptical at first but went along with Paley and did the installation. After a 30-day pilot program and many conversations with Greffen's team Mitchell, Richmond and Paley were thrilled that there was a significant reduction of energy consumption (12%) with the M2G unit. "This is a game changer," said Mitchell. Thus, Commercial Energy Solutions, LLC, Greffen's exclusive New England distributor of the M2G intelligent boiler control device for closed loop hot water boilers was formed by Mitchell and Richman.

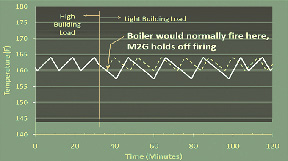

Designed by boiler experts in Europe, the M2G is a boiler control microprocessor that determines if a real request for heat on the boiler exists, or if the boiler is dry-cycling. If it is determined that a real call exists, the boiler is immediately released to fire. If it is determined that there is a false call for heat, the dead-band is automatically increased from 2.5 degrees to 14.5 degrees or 15 minutes (whichever occurs first) before allowing the boiler to fire. The microprocessor checks for real calls every 10 seconds and dynamically responds to boiler requests. If at any time during the increased dead band cycle, or 15 minute cycle, the boiler receives a real call for heat, the boiler will be allowed to fire. Finally, because real calls for heat from the boiler are not interrupted, the comfort levels of the building occupants are not adversely affected. The interior temperatures remain consistent with those temperatures achieved before M2G installation.

Greffen Systems recently acquired United States distribution rights for the M2G, a British microprocessor product that reduces the number of times that hot water boilers cycle. Commercial Energy Solutions located in South Windsor, is the exclusive distributor for New England. Mitchell Fuel Company is the installer for this unique device that applies proven algorithms to allow the temperature to drop below typical set points only at times when this can be done without impacting the system's ability to deliver necessary heat inside the building. The M2G essentially acts as a cruise control, replacing the stops and starts that plague most hot water boilers with more efficient cycling that is analogous to steady highway driving.

"Basically, the M2G is a microprocessor that uses algorithms developed by engineers in Europe," said Mitchell. "It reduces the number of times that a boiler cycles by learning its thermodynamics, so it can differentiate between real and false calls."

Boiler control mechanisms that only monitor temperatures inside the boiler create a very limited picture of what may be causing temperature changes. The M2G measures water temperatures at the inlet and outlet of the boiler. It also tracks another vital variable that aids in its understanding of the building's thermodynamics. "The two sensors don't only measure temperature, they measure temperature over time," said Mitchell. "Instead of providing a photograph to work with, they give the M2G a movie."

The return on investment is between 6-16 months on average. Once the M2G is installed, it needs no maintenance to operate; it simply learns when it can let the boiler cool down without sacrificing performance.

"You install it, walk away, check your bills and save money. In other words, don't waste your energy; just save it," said Richman.

Tags:

Commercial Energy Solutions is the exclusive distributor of the M2G hot water boiler system in New England

August 19, 2010 - Connecticut