Asbestos is a group of naturally occurring minerals with long, thin fibrous crystals. It is sometimes referred to as the "miracle mineral" because of its beneficial properties such as insulation and fire protection. In the United States, chrysotile is the type of asbestos used most commonly.

Its long fibers are often found in a wide variety of materials such as vinyl floor tiles, mastic, sheetrock, joint compound, shingles, siding, and thermal pipe insulation. Asbestos has had many positive uses including heat resistance, electrical insulation, flame-retardant and insulating properties, resistance to chemicals and great strength and flexibility. Even though asbestos seemed to be the perfect material to improve many things, the phrase "yesterday's solution is today's problem" is very true. The inhalation of asbestos fibers can cause serious diseases such as asbestosis and mesothelioma.

Because asbestos has had so many uses, it is found in virtually every building that is presented to the market for renovation. Today, asbestos is such a serious health hazard that many countries have banned its use since the 1980s.

We at EnviroVantage have been dealing with asbestos abatement for over 25 years and have developed expertise in recognizing the best techniques as well as continuously coming up with innovative ideas to remove environmental hazards. When we combine that expertise with our selective demolition skills, mold remediation and lead abatement knowledge, we ensure that the developer / renovator does not have to stop a project due to the discovery of an unexpected hazard.

For example, we recently teamed up with Harvey Construction in a renovation project that involved a great amount of asbestos abatement combined with intense selective demolition - exactly the type of combination of needs in which we excel. The project was at Phillips Exeter Academy in Exeter, N.H. EnviroVantage was selected to take on Phase I of the long overdue Central Boiler Plant renovation project.

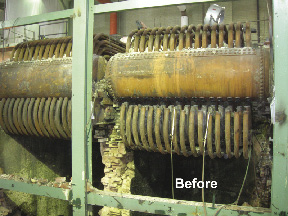

There were originally 6 enormous boilers incased in layers of brick and asbestos that dated back to the early 1900s. The replacement of these old boilers with new, more efficient boilers greatly increases the steam production efficiency of the heating plant, saves time and money, and eliminates unnecessary risks to the employees working in the plant.

Phase I started with thousands of linear feet of asbestos removal from live steam lines, which was resourcefully coordinated by one of EnviroVantage's most experienced asbestos supervisors, Pete Carlberg. Asbestos pipe insulation was to be removed using glove bags. This soon presented a dilemma because when the insulation was removed, the sheer heat of the pipes melted the bags and even the gloves of the men working on them. The pipes required at least 3 to 4 days to cool down, even after being shut down and drained. Despite the extreme conditions of the heat from the raging hot pipes, on top of the sizzling summer temperatures confined inside the containment making it feel like a sauna, the asbestos workers never missed a beat.

Next, EnviroVantage jumped right in to the demolition portion of the project. We began the process by demolishing the suspended steam lines, ranging from 8 to 14 inches in thickness that needed to be removed. This was a dangerous task as the workers needed to maneuver around live steam, and gas lines. Chain falls, forklifts, and bobcats were utilized to lower the pipes from the ceiling.

While hauling out load after load of brick, several torch cutters were used to cut the steel tanks and tubes down from each set of boilers. Each shell had about 150 steel tubes connecting the tanks together, all of which were meticulously cut into sections, lowered down and hauled out. EnviroVantage then cut down the rest of the steel structures along with all of the beams and supports, leaving a bare floor and ceiling. 100% of the metal was recycled, the concrete went to a concrete crushing plant, and all other general waste went out separately to the appropriate places.

Flexibility, innovative techniques, out-of-the-box thinking and teamwork all helped to overcome the unexpected, and go above and beyond the needs of the contractor and the owner. The successful completion of this project increased the trust and satisfaction that PEA has with EnviroVantage, and will help us to continue our working relationship for many years to come.

Scott Sansoucie is vice president with EnviroVantage. Epping, N.H.

Tags:

EnviroVantage completes boiler plant asbestos removal/demo project at Phillips Exeter Academy

July 29, 2010 - Spotlights

.png)