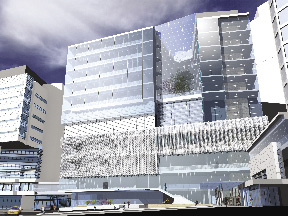

As Massachusetts General Hospital prepares to celebrate its bicentennial anniversary in 2011, construction is underway on its Building for the Third Century (B3C).

The B3C is a 530,000 s/f inpatient medical facility that expands the existing hospital with state-of-the-art emergency rooms, procedure rooms, patient rooms, and services. Blending the infrastructure of a modern building with the existing functions of an operational hospital offered some unique structural challenges. Limited site area, matching program spaces, plan irregularities, and accommodations for the latest medical technology dictated the use of multiple structural building materials and systems to serve the programming needs of the different hospital spaces.

McNamara/Salvia, Inc., project manager John Tracy, P.E., LEED AP, said, "The primary design objective was ensuring that the hospital had the clearances and flexibility to use the latest medical technologies to best serve the needs of their patients. Some of the structural elements may appear unconventional, but they were carefully considered with patient care objectives in mind."

The limited site for the B3C is bounded on one side by the existing emergency room entrance that needed to remain operational 24/7 during construction. On two other sides were existing, operational hospital spaces with sensitive patient care functions. The fourth side of the site was Fruit Street, which serves as an entry point to adjacent outpatient buildings. These tight urban boundaries dictated the use of up-down construction to streamline the construction schedule and maximize contractor lay-down area. The foundation consists of concrete diaphragm (slurry) wall panels at the perimeter and interior columns encased in load-bearing element (LBE) foundations. The down slabs are mild reinforced two-way concrete slabs, constructed as the steel frame was erected above. Normally reserved for underground parking, the basements at the B3C are uniquely occupied by clinical patient and hospital support services.

The site also dictated that receiving and ambulance entry functions are located within the building footprint. To accomplish this space, a one-story high transfer truss spans over the loading dock to support the moment frame above. The interior ambulance bay is column free thanks to a structural system suspended by hangers from the floors above.

For the B3C to expand the functions of the existing hospital, the lower procedure floors are designed to match the elevations of the existing buildings. The resulting low floor-to-floor heights left little room to accommodate the infrastructure required in modern procedure rooms with conventional structural steel and composite deck construction. To expand the space in the procedure rooms, precast prestressed hollowcore concrete planks were selected to span between upset structural steel beams framing to hangers from the floors above. Only 12" thick, the resulting structural floor plates leave the ceiling space to accommodate the latest medical technologies.

The programming plan and irregularities of the site discouraged the use of a central core for centralizing the lateral frame of the structure. Cantilevers were used to maximize patient room space on the upper floors and columns were transferred to a uniform grid to allow modular patient room. Since diagonal bracing would interfere with the flexibility of the space, moment frames were used for the lateral load resisting system at the perimeter of the building. Due to the occupancy category, Special Moment Frames were required and prequalified Reduced Beam Sections (RBS) were selected. Shear links were used at the transfer levels to provide additional lateral stiffness and help meet the code requirements for the hospital as an essential facility required for post-earthquake recovery.

With medical equipment constantly evolving and improving, the B3C needed to be designed with the flexibility to support new ceiling-hung or floor-mounted equipment without disrupting the operations of spaces above or below for future reinforcement. Additional reinforcement was strategically placed in the slabs and floor capacities were locally enhanced based on program to allow new and future equipment to be flexibly located and mounted directly to the floor slabs from above or below. Most of the equipment has strict serviceability requirements for which supports were analyzed up front to reduce future impacts to the space.

With enhancing patient care an objective in all decisions, the highly coordinated efforts of the design team and construction team on the B3C project have produced a building that serves the needs of the hospital now and in the future.

Mass. General Hospital- B3C project team

Construction Manager: Turner Construction

Structuural Engineers: McNamara/Salvia Inc.

Associate Deesign Architect: Chan Krieger Sieniewicz

Concrete: S & F Concrete Contractors, Inc.

Structural Steel Fabricator: Isaacson Structural Steel. Inc.

Tags:

McNamara/Salvia begins construction of Mass. General Hospital's 530,000 s/f Building for the Third Century

November 24, 2009 - Front Section