When it comes to creating safe and healthy indoor environments, building operators and business owners have no shortage of information and resources available. Some of the recommendations are easy to implement, some are not so easy, and a few suggestions conflict with each other. While this is one topic that has long been a goal for many business owners, it is even more important today as many businesses are preparing their return-to-work strategies.

Combining technologies with maintenance and controls can go a long way toward reducing health risks in your building

For many organizations, it’s not just a matter of when to bring employees back into the workplace, it’s also a matter of how to do so as safely as possible and how to provide confidence to employees and visitors that effective measures are in place. Building operators have so many questions: Can I increase my air filter MERV rating? Should we reconfigure workspaces? What about health checks? How will our cleaning processes need to change? … to name a few.

There is no simple, one-size-fits-all answer. There just isn’t.

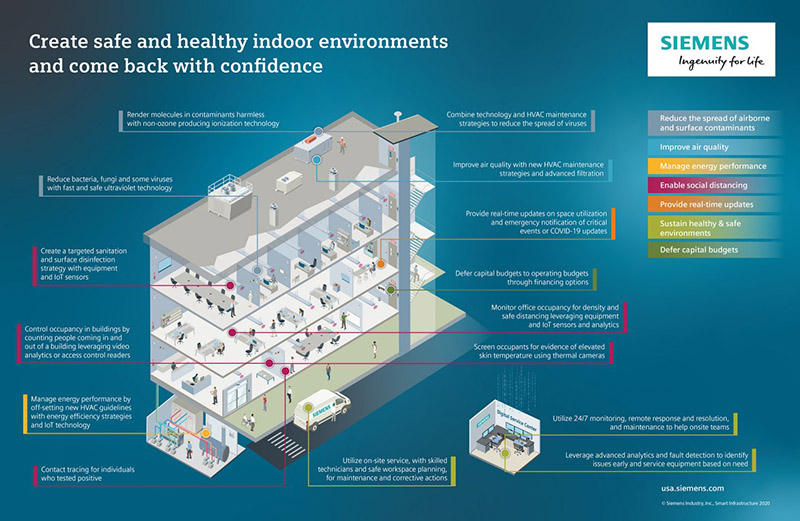

What we do know, however, is that your building’s mechanical systems can play a role in a safer return-to-work strategy and help allay some of the fears many employees may have about emerging from stay-at-home/remote work arrangements. The goal, of course, will be to create a safe and healthy indoor environment; one way to work toward this goal is to reduce the health risks to employees and building occupants by reducing the spread of airborne and surface contaminants.

Emerging research in this area is pretty clear–viral spread is linked to the presence of fine particles and contaminants in a building. And although correlation is not causality, it does seem that viruses are spreading where those contaminants are more prevalent. As a result, it makes sense to find ways to help minimize viral spread by reducing the number of indoor contaminants.

We can do this in a variety of ways by leveraging your building’s mechanical systems, and a range of effective technologies that are already available to us. UV light technology is one way; so too is Needlepoint Bipolar Ionization. Filter MERV rating upgrades and advanced filtration (air scrubbers) are other great ways to treat the air as it flows through your building and ventilation systems. Selecting the appropriate technologies with precise system control can quantifiably improve the indoor air in your building–and you can use a range of key performance indicators (KPIs) to monitor the quality of the indoor environment in your building(s). These may include building differential pressure, fine particulate counts, room temperature, and room humidity levels as compared to agreed-upon baselines, benchmarks, or setpoints. Properly maintaining your mechanical equipment can also go a long way toward reducing health risks in your building.

Siemens’ solution partners have provided promising test results of their technologies’ efficacy against viruses and bacteria, yet we emphasize the importance of a holistic approach when it comes to infection prevention as there is no single solution today that is 100% effective in removing all contaminants.

Today, we’re fighting the COVID-19 (SARS-CoV-2) virus, and tomorrow it could be something else entirely–or even something as common as a new strain of influenza. Regardless, leveraging your building’s mechanical systems to incorporate new technologies and approaches should be considered to help reduce the spread of airborne and surface contaminants and help you come back with confidence.

David Santo, segment head for smart mechanical services, and Alex Yashkevich, healthcare portfolio manager at Siemens, Pompano Beach, FL.

(1).png)