Developers bringing-in projects ahead of schedule and under budget aren't turning back to the wasteful old ways that still hamstring much of the construction industry. Why would they? They can often work 20% faster, 15% below budget and 30% more efficiently - at a minimum.

"I'm sold," on new, more efficient construction methods, said John Messervy, director of capital facilities planning for Partners Healthcare, among New England's largest developers. He expects to save close to $75 million on its two latest projects: the $225 million Spaulding Rehabilitation Hospital and $500 million Brigham & Women's Building for the Future.

"We can now resolve an issue in five minutes that would have taken two weeks in the past," said Richard Martini, EVP of operations for The Fallon Company, another proponent of efficient construction who just completed the $1 billion, 1.1 million s/f lab and office headquarters for Vertex Pharmaceuticals in Boston, which was the nation's largest private construction project when it started in 2011. "Everyone on the development team met weekly in the same room, with iPads, instantly sharing real-time information, and agreeing to change layouts on the spot. Before, we'd have to send sketches back and forth, try different solutions; relationships between subs were adversarial, and when we got in the field—oops, things didn't fit."

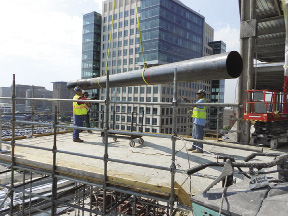

J.C. Cannistraro, a 51-year-old, family-run, mechanical construction firm that has developed an innovative, collaborative approach, did the massive job of providing all, or part of, the mechanical systems for the two-building Vertex complex, Spaulding Rehabilitation Hospital, projects at Logan International Airport and many other major jobs in the region by "building with intelligence." That means extensive pre-construction planning; coordinating schedules; maximizing efficiency and the amount of real-time data available by managing an integrated BIM-enabled software platform for the entire project team with up-to-the-minute details of the design, layout and the metrics of each piece of equipment. Cannistraro pre-fabricates thousands of parts in its shop, delivers them to the site just-in-time to hoist and install within a day or two.

"This approach helps avoid the common but costly problem of changing the design during construction. Without team-wide pre-construction planning, buildings can rarely be built as initially designed. Miscommunication and incomplete design can then lead to rework and costly delays in the field. Meticulously planned collaboration is the modus operandi for the latest, more efficient construction methods. Team members are motivated to cooperate and master the design/development IT platform to become an industry leader who will be hired for future work and to capture the financial windfall for success that's structured into a contract. The developer is driven by the prospect of having an immutable budget, despite expanding the scope of work, and by owning a higher quality, more valuable building," Messervy said.

"Technology is revolutionizing how construction is done and monitored," said Chris Gordon, CEO of Dirigo and a lecturer on construction at the M.I.T. Center for Real Estate. With BIM, wireless and cloud-based technology recently becoming more affordable, "Every project team member can always access up to date information, real-time, and monitor tectonic shifts in the earth anywhere in the world."

"These technological advances encourage collaboration; whereas, in the old days, people fought over everything. Construction may not be worse than some other industries, but it can still do more planning, pre-fabrication and modular building," Gordon said.

Indeed, construction's prevailing inefficiencies can lead to huge financial losses. By one estimate, 46.5% of the entire labor cost on a project is lost as trades people wait for parts or for others to complete their slice of the job, said construction attorney Barry LePatner who customarily represents owners and developers.

One reason for the waste is the structure of contracts that don't set a fixed project cost; they allow-even encourage-expensive change orders, LePatner added. Also, fast-track projects that start excavation and construction before architects and engineers complete plans or understand the full scope of work often run over budget.

Pre-construction planning by the entire team leads to the most successful projects in terms of quality and budget. Once the clock starts ticking in the field, there's no time for ambiguities. If the entire team of trade contractors is brought onboard during the design process, months before a shovel hits the ground, it is entirely reasonable for a contractor to guarantee zero change orders.

Overall, however, productivity in the construction industry is steady or declining slightly, said Associated General Contractors of America chief economist Ken Simonson. He estimates that 30% of the time on-site is spent waiting to resolve problems that lead to change orders or for architects and engineers on fast-track projects to figure out the next move at the site.

Wayne Crews, director of the Construction Industry Institute at the University of Texas/Austin said industry productivity is declining .4% a year; the average worker only spends about 35% of time on-site actually working at their trade. Instead, trade contractors and their workers are spending time looking for equipment, waiting for others to finish what they're doing and striving to boost their competitive advantage at the expense of the other contractors and of the entire project.

"We have a long way to go to make construction safer and more productive," Crews said. "The major trades can improve productivity by 40% to 50%."

Part of the problem is innate, "Each construction project is unique," said John Macomber, Senior Lecturer in Finance at Harvard Business School and former CEO of Macomber Construction. On every project, usually there are dozens of companies that haven't worked together before. Unlike GM and Firestone, they haven't built a lasting supply chain for the thousands of parts they use, from 4-inch elbows to elevator wheels. They're subject to one-time thinking, which does not encourage investing to enhance productivity.

"Meanwhile, contracts formulated in the 1960's that promote use of the critical path operational method, pressure each subcontractor to bring-in their portion of a job on-budget rather than maximize the efficiency of the entire project," said Greg Howell, a founder of the Lean Construction Institute. A trade contractor will reach their weekly goal only 54% of the time, according to a recent LCI survey. "Whether or not the work gets done is a coin toss," not great odds, Howell said.

But, being able to build cheaper, smarter, faster is increasingly important as commercial real estate development revives in major urban markets and construction costs rise. Furthermore, buildings are getting bigger with more complicated facades and infrastructure. Inventive new shapes with more glass and curves are made possible by computer generated design. Old towers usually had one mechanical penthouse; now, a high rise may have two or more to service complicated systems for HVAC, IT and electrical conduits. But owners seeking to gain rentable space may request lower floor to ceiling heights that leave even less shaft space for the greater number of ducts and pipes needed.

Like many businesses, construction is composed of myriad details; attention to them is paramount if a project is to succeed.

For Cannistraro, the focus on technology and new strategies has meant transitioning its own 500 -person staff by reducing the number of onsite mechanics and moving most work to the prefabrication plant. At the same time, these technologies are changing the demographics of the office by helping to recruit and retain a young, intelligent, tech-savvy workforce.

On a big job, Cannistraro will spend four to six months in pre-construction planning to maximize quality and efficiency. It uses its decades of construction expertise to develop an integrated BIM software platform for the entire project team: owner, architect, engineers, general contractor, key trades and other specialists. The company may spend as much time planning as doing the actual construction because it can save thousands of hours in the field.

For Cannistraro's part of the Vertex project-installing the fire protection in both buildings and HVAC in one of them—the firm took the initiative to manage and coordinate pre-construction planning with all the other trade contractors and professionals. With one coordinated model for the whole team, they could instantly share updated files thus creating highly detailed and accurate 3D construction documents.

In May at its Wilmington factory (two months before the first delivery), Cannistraro started to prefabricate, number and properly sequence about 2,000 piping spools.

In July, the Cannistraro installation crew of 20 arrived on-site. The numbered parts were delivered to be installed immediately and virtually problem-free since they were pre-fabricated to exacting standards. This minimized expensive changes. By early November, the entire mechanical and heating system for their contract was operational.

Using the old-fashioned "stick-built" methods, the piping raw materials would have been loaded onto the floor in bulk, where they would sit in piles for months, while a crew double the size chipped away at it.

Not only did Cannistraro deliver its part of the job on time and on budget, "they took the lead in file sharing with the rest of the team," Martini recalls. "At our weekly meetings, JCC coordinated with all the other subs. During the rest of the week, they shared information, uploaded documents, and resolved issues."

Cannistraro shaved by 50% the time required to complete its critical part of the complex lab/office project and saved at least 20% on the total cost of the mechanical system design, production and installation, Cannistraro estimated.

The end result for The Fallon Co., the developer of the Vertex complex: the tenant has moved and Fallon is already marketing the building for sale.

For the $200 million Waterside Place, a 236-unit rental apartment building developed by The Drew Company, Cannistraro's approach helped shave time off the construction schedule.

"All the technology and planning has improved design and construction phenomenally," said John Drew, CEO of The Drew Company. "It will do the same for running the building because we'll be able to easily track down problems."

Drew and other developers who design and build focusing on pre-construction planning, technology, collaboration, pre-fabrication and efficiency as paramount drivers get lower cost but better buildings.

John Cannistraro, Jr. is president of J.C. Cannistraro, LLC, Watertown, Mass.

(1).png)