A two-year trial of a fuel injector for oil fired heating systems ended in August, with results from over a dozen sites showing reductions in oil consumption of 22%-32%. The system, The Burner Booster, also cut the emission of greenhouse and other harmful gases by 22%-75%.

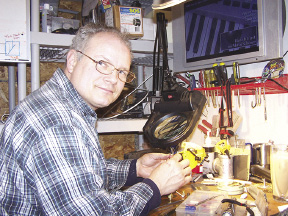

Burner Booster inventor Eric LaVoie said, "The Burner Booster is a high-pressure system that acts like a fuel injector for oilheating systems-creating a mist of oil that dramatically improves combustion efficiency and represents the first major advance in oil heating technology in decades. It's a patented and proven technology that's safe, easily installed on existing heating systems, and can pay for itself in just over two years."

LaVoie said, "Following the success at our test sites, we've asked Nelson and Small Conservation Products, Inc. (Portland, Maine) to sell, install, and service The Burner Booster through their network of oil heat service companies throughout New England. We've also lined up lenders willing to provide financing to individuals and companies and lease to own options to municipalities."

Nelson and Small president Ken Nelson said, "After seeing The Burner Booster in action and the enthusiastic response of hundreds of local heating service dealers we know this technology is the wave of the future. For larger commercial customers the return on investment can be less than two years. We're excited to be a part of it."

In November, 2011 The Burner Booster received national safety listing following rigorous safety testing by ETL Intertek, a nationally-recognized UL-standards testing company. The safety listing for #2 and #4 heating oil and all bio-blended fuels certifies the system for installation in commercial operations, municipal buildings, institutions, and homes throughout the United States.

Trial sites in Mass. and N.H. include two correctional facilities (MCI Plymouth and DYS Metro Youth Center), Town of Needham public facilities department, Manchester (NH) waste water treatment facility, New England Easter Seals headquarters, an elementary school, college, factory, and several private homes.

Air quality comparison tests conducted to EPA standards by CK Environmental, Inc., using the same oil burning heatingsystems with and without The Burner Booster reported reductions in carbon dioxide of 22%, sulfur dioxide of 28%, nitrogen oxide compounds of 32%, and carbon monoxide of 65% and sulfur monoxide of 75%.

At the current market price of $3.60 per gallon of heating oil, The Burner Booster can save a 3,000 s/f business or home around $2,500 a year. Priced at around $6,500 with installation for the smaller systems (including installation), and a three-year warranty on parts, The Burner Booster can pay for itself in just over two years. Larger systems will cut oil use even more and achieve an even faster return on investment.

Town of Needham public facilities director Chip Laffey said, "We saved nearly 30% in one facility. With the installation of The Burner Booster in our larger facilities, we'll be able to see reduced oil consumption, maintenance, and emissions."

Bob Jewett, general manager of Acme Staple Company, Franklin, New Hampshire said, "Prior to installation, we burned an average of 55 gallons per day. The results since installation have been in the range of 25-36 gallons per day, a clear reduction in excess of 30%. One of the improvements is the cleanliness of the combustion chamber and the absence of particulates in the exhaust."

Tom Farrell, director of facilities of Easter Seals of New Hampshire said, "The Burner Booster has allowed us to save over 1,200 gallons per year in our 64,000 s/f headquarters building."

Nationally, over 12 million homes, businesses, and institutions heat with oil.

The Burner Booster is produced by Energy Efficiency Solutions, LLC.

Tags:

Fuel injector for oil heating systems hits the market

December 06, 2012 - Owners Developers & Managers

(1).png)