How can construction professionals prevent tragic crane and delivery truck loader accidents?

LJ Crane & Rigging, Warwick, in cooperation with the safety committee of the Rhode Island General Contractors Association recently held a day-long seminar at the LJ C&R Jefferson Blvd. site aimed at promoting best practices and preventing mistakes that too often lead to tragic results. Attended by well over 100 professionals, it was the second annual all-day seminar the company has hosted and generously sponsored on crane safety.

After introductory remarks by Patrick Griffin, OSHA's Providence area director, Darious Wenger, crane technical training instructor for Manitowoc/Grove, Manitowoc, Wis., addressed mobile and crawler crane safety, illustrating the uses and misuses of different types. Never use cranes for bungee jumping or for pushing or pulling, for example. He discussed operator responsibilities and crane setup with properly extended outriggers and enough tightly stacked cribbing to support the load as well as the need to consider weather and jobsite conditions, such as possible underground culverts, utilities or sink holes. Additional topics included a crane's limitations, load charts, industrial safety standards, electrical safety, personnel handling and crane maintenance.

Joel Oliva, program manager of regulatory affairs for the National Commission for the Certification of Crane Operators (NCCCO), Fairfax, Va., explained the operator certification process, which - unlike licenses - includes a practical exam in its rigorous testing program as well as 40 hours of classroom study. With many contractors requesting operators with NCCCO certification, industrial safety experts such as Bob Renzi, director of safety & training for the LJ Companies, foresee certification becoming a mandate within five to 10 years. He said 80 percent of the operators at LJ Crane already have NCCCO-certification in addition to their licenses.

Rigging Safety

Many accidents can be prevented with careful maintenance and inspection of rigging before each job, according to Jim Harkin, product safety specialist in the Stoughton, Mass., branch of I&I Sling Co., Aston, Penn. He noted several safety measures and care that must be taken to ensure safety devices as well as the rigging are in good working order. While metal rigging can be seen and checked on the ground, it is nearly impossible to see damage that may occur during operation as is possible with some synthetic round slings with built-in safety measures. All rigging, however, needs to be carefully monitored and maintained.

For example, he said that operators must ensure that fiber optic tubes embedded in some synthetic round slings have not been subjected to too much heat or set on the ground and accidentally crushed along with the load-bearing fiber. In others, there may be telltales that, if missing or if one is shorter than another, signal that the sling should be taken out of service. Harkin also passed around a damaged synthetic web sling to show how an operator should feel for damage with ungloved hands. For example, feeling a bunched-up section that appears as though the snake-like sling has "swallowed a mouse" indicates broken fiber and the necessity to take the sling out of service immediately.

Third-Party Crane Inspection

Ed Shapiro, principal owner and operator of Heavy Equipment Service Co. (HESCO), East Lyme, Conn., explained the complexities of crane inspection, and the benefits of having owners use experienced inspectors. There is no accreditation required for state licensing, but inspectors certified by the Crane Certifiers Association of America must be recertified every two years or qualify with required continuing education credits.

Articulated-Boom Delivery Trucks

"Loaders," or "day-trippers," that deliver materials to construction sites also must be operated and maintained by experienced and conscientious personnel to avoid potential disasters. In addition, construction sites must be properly prepared to receive them on a schedule that should take into consideration other deliveries, traffic and the type of work that may be taking place nearby, according to Robert Kunz, corporate safety director for Dimeo Construction Co., Providence. He said factors that can contribute to a shifting load and a truck rollover, for example, include frozen ground that can soften or stabilizers that are not fully extended on firm, level ground and/or inadequate cribbing. The operator must demonstrate knowledge such as the weight of materials being delivered and the weight of the rigging gear, which together must be within the rated load capacity of the delivery truck.

Kunz recommends increased communication among the materials vendor, delivery truck company, subcontractor ordering the supplies and the GC, and use of a site delivery board to show the site utilization schedule and increase worker awareness of job site activities. In addition, a checklist detailing best practices should be used at each site to ensure all procedures have been implemented and all required documentation is satisfactorily completed.

OSHA Enforcement

James Holliday, Providence area OSHA compliance officer, outlined his inspection procedures and showed photos of flawed crane set-ups and conditions. After watching a crane work to see if the load is jumping or the main lifting cable is spooling correctly, and after asking the operator's permission to enter the cab, he checks such documentation as his or her license to operate that particular crane and a hard copy of the inspection report. He then checks such items as the gauges to ensure all are operational, levers to make certain they are labeled according to ANSI standards, and glass to make sure there are no cracks to obstruct the operator's view.

Holliday also showed photos of some violations that required him to take cranes out of service. Among them was a demolition crane with a tire joining two cables to provide bounce flexibility for a two-ton wrecking ball - a sure recipe for eventual tearing of the tire and disaster. Other such violations included a crane on a barge that was not secured, crane levers that were leaking oil, and cables that showed damage such as kinks, fraying and welding torch burns.

Crane Lift Planning

Safe-lift planning is a rigorous process. In the case of a critical lift, such as the lift of a pedestrian bridge described by Rick Bockman, senior New England regional safety manager for Gilbane, Providence, and Bob Renzi, the LJ Companies' director of safety & training, it may require months of planning, coordination, permitting and inspection processes. Gilbane's Bockman pointed out that technology, such as the LJ Crane database of crane parameters and pick situations, can streamline some of the process. While thorough pre-pick jobsite inspections are a must, checking all computer-generated information for each pick helps with development of the plan and accurate communication among different parties involved.

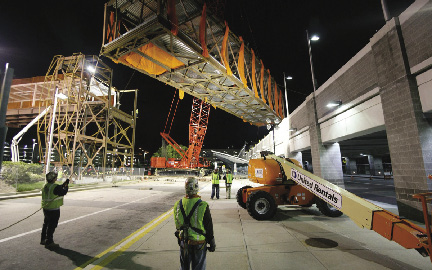

Renzi described the detailed planning documents used to gather information for worst-case scenarios of each pick. He also emphasized that common sense is a key ingredient to a safe pick, and said that LJ's crane operators had full authority to halt a pick with which they were not comfortable. An example of such a condition might occur if wind gusts at the time of the pick were too great, and he mentioned that most LJ cranes had anemometers so operators can accurately assess wind speeds. He also showed a video (see http://www.ljcrane.com) of placement of a pedestrian bridge, part of a Gilbane construction management project, at Providence's T F Green Airport. This lift also required coordination with the FAA and took place after the last plane had landed for the night. Because of the nonsymmetrical configuration of the walkway, a test pick was done several days ahead of time to determine exactly how to adjust cables to balance the load.

The seminar ended with raffle drawings for personal protective equipment and other items donated by New England Highway Technology, Cranston, R.I., Shawmut Equipment, Manchester, Conn., and the LJ Companies. USI Insurance Services donated the grand prize: box seat tickets to a New England Patriots game.

.png)